Yasda’s 5-Axis precision machine tools have a great potential to improve milling performance on difficult-to-cut materials for the Aerospace Industry, mainly due to their outstanding high rigidity as well as their high machining accuracy.

Originally Yasda’s horizontal machines were designed to achieve the highest milling accuracy on precision components. The first 5-Axis horizontal model was developed in 1992. Yasda has a consistent concept to provide the highest rigidity in every base component in order to achieve the highest milling accuracy. We have found in this decade that rigidity and structure also contribute a lot in machining difficult-to-cut materials for the Aerospace Industry. The use of our hand scraping process in each key assembly also helps provide long-term reliability in machining accuracy and performance.

Seven examples of Yasda’s contributions to Aerospace applications:

- Outstandingly high machine rigidity. In our recent inspection research, we determined that our dynamic rigidity (tap test) on our YBM horizontal machines recorded far more than double, compared to several other brands of Japanese horizontal machining centers. That results in the best cutting performance when milling Titanium, Inconel etc.

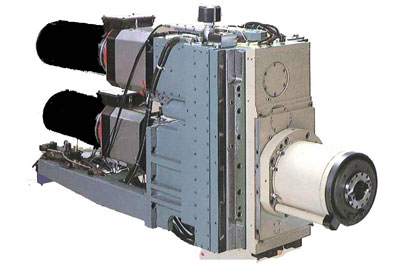

- Outstandingly robust in-house built spindle with a long life. Yasda’s original Preload Self-Adjusting system draws out the best performance of every tool.

- Each model has extra-rigidity in pallet clamping support system and in every guide way. Guide ways are through hardened box guide ways for the YBM series, and rigidity type LM guide ways for PX series. Every model has large mating faces between the guide ways and the motion unit, normally double in size compared to other general machines.

- Yasda designs the largest and heaviest machine mass for each size model. This allows each Yasda machine to utilize the highest damping capacity to absorb cutting force when milling difficult-to-cut materials.

- YBM7Ti has a unique construction called table-on-table style, having an in-house manufactured rigid DD motor driven table. YBM7Ti is suitable for finishing turbine disk or blisk of Titanium or Inconel, valve components, parts for landing gears, parts of hardened steel, etc.

- H40i also has a table-on-table style, having a faster machining capability of smaller components, e.g. actuator parts, turbine disk and turbine blades of Titanium or Inconel, gear boxes, parts of Aluminum or hardened steel, etc.

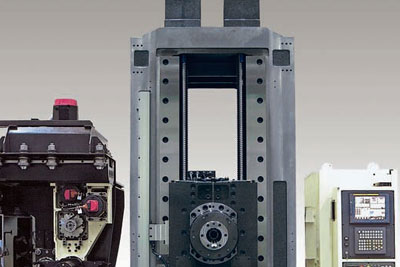

- YBM10T-TT has a unique mono-block trunnion table with twin servo drive motors on both sides. Second to none, this model has the highest rigidity of this size 5-Axis horizontal machining centers. YBM10T-TT is suitable for milling on engine cases of Titanium or Inconel. Our YBM10T-TT has an outstanding reputation with Japanese manufacturers when milling jet engine cases.