YBM 7Ti

HORIZONTAL 5-AXIS PRECISION CENTER

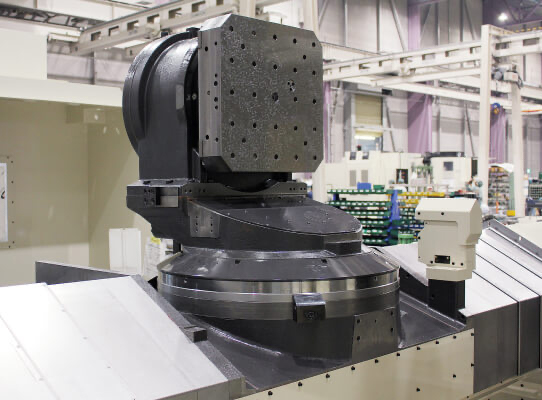

YBM 7Ti is a table on table 5 axis machine employing high power DD motors on B and C axis.

KEY SPECIFICATIONS

Accuracy (X,Y,Z): 2.3, 3.0, 2.7μm

Travel (X,Y,Z): 1,250 x 1,000 x 1,100mm / 49.21 x 39.37 x 43.30inch

Loading Capacity: 500kg / 1,102.31

APPLICATIONS

Machine Structure

YBM 7Ti's table unit with high power DD motors, and high rigid bearings, demonstrates superior machining capability for high speed, high precision machining, difficult-to-cut materials, and heavy duty cutting. In addition, due to highly precise rotational axis control, it achieves backlash-less operation and quick response machining.

Box Guide Way

YASDA's traditional hybrid box guide ways driven by Twin Ball screws. The box guideway is fastened to a hand scraped mounting surface in order to minimize Roll, Pitch and Yaw error of each guideways and thus to achieve high straightness and geometric accuracy.

Spindle

The preload self-adjusting spindle developed by YASDA realizes a high degree of accuracy throughout the whole speed range.

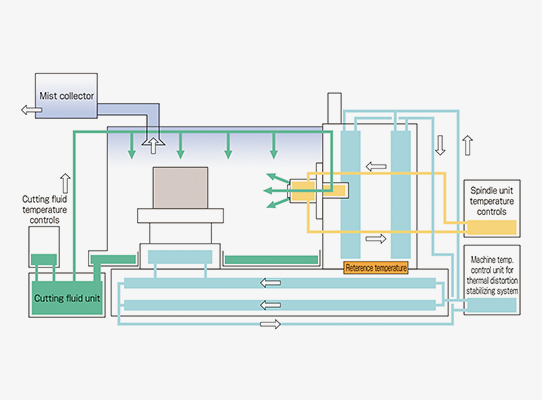

Thermal Distortion Stabilizing System

Measures against thermal displacement have been developed based on YASDA's decades long experience and technological advancements. YASDA's unique system blocks rapid thermal distortion and maintains stable high precision machining.

NC

15" touch panel display mounted with FANUC iHMI interface and YASDA's User interface "OpeNe Version 2.0" provides intuitive operation and high functionality. The "OpeNe version 2.0" provides the operator with innovative solutions and complete details of the machine.

ATC/APC

ATC: YBM7Ti is equipped with an automatic tool changer (ATC) with 60 tools standard. With additional magazines the number of tools can be expanded up to 450 tools.

APC: Automatic pallet changer (APC) is standard. Pre Load Stand (PLS) is also available as option.

SPECIFICATIONS

| Specification | YBM 7Ti | |

|---|---|---|

| Accuracy [ISO230-2 (2014)] | 2.3, 3.0, 2.7μm | |

| Travel (X, Y, Z-axis) | 1,250 x 1,000 x 1,100mm | 49.21 x 39.37 x 43.30inch |

| Travel (B) | ±110deg | |

| Travel (C) | 360deg (Continuous) | |

| Pallet Working Size | 500 x 500mm | 19.69 x 19.69inch |

| Spindle RPM | 10,000min⁻¹ [6,000min⁻¹ / 15,000min⁻¹ SA type (op)] | |

| Spindle Taper | BBT50 [HSK-A100 (op)] | |

| Max Workpiece Dimension | Dia. 630 x 500mm | Dia. 24.80 x 19.69inch |

| Maximum Loading Capacity | 500kg | 1,102.31lbs |

| Rapid Traverse | Max. 45,000mm/min (X), 48,000mm/min (Y,Z) | Max. 1,771.65inch/min (X), 1,889.76inch/min (Y,Z) |

| Table Rotation Speed (B) | 70min⁻¹ | |

| Table Rotation Speed (C) | 100min⁻¹ | |

| ATC Capacity | 60 tools [Max. 450 tools (op)] | |

| Axis | 5 | |

| Type | Horizontal | |