Yasda developed the first machining center YBM50J JIG MASTER in 1964. Since the beginning, Yasda targeted parts which required the highest milling accuracy, such as machine tool components, components for factory equipment: printing machines, injection molding machines, high-speed press machines, vacuum pumps and compressors, jigs and fixtures, etc.

Yasda has a clear concept in manufacturing our machining centers. Hand-scraping every key mounting face of the base components achieves the highest accuracy. In addition, we make our machines with extra-high rigidity in order to sustain their high machining accuracy for a long time. Today, together with the development of software compensation and tooling, it is not easy for customers to distinguish the difference of parts milling capability of each machining center.

Yasda sustains its unchanged concept to achieve the highest milling accuracy, and can offer solutions anytime what could be achieved in your precision milling.

Our in-depth knowledge of the technology of precision parts includes:

- Experience of 2,000 global installations of our YBM horizontal machines.

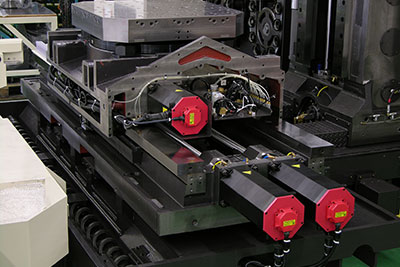

- Experts of turn boring solution. The highest turn boring accuracy obtainable in the market with the longest experience.

- Established market recognition as “mother machines” due to the fact that many machine tool builders are using our horizontal Precision Centers to finish their core components, e.g. spindle head, 5-Axis table unit, turret, saddle, bed, etc.

- Almost identical high machining accuracy between the different sizes of our machines, due to our hand scraping process.

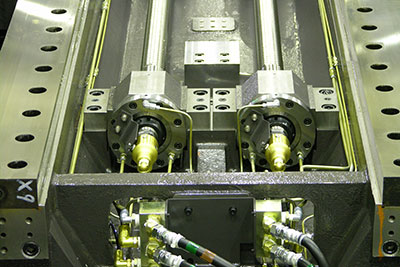

- Reliable in-house built spindle with a unique design of direct drive has an outstandingly high run-out accuracy in milling.

- Through hardened box ways help sustain outstanding repeatability at any position of the work envelope.

- Yasda’s original thermal distortion stabilizing system helps sustain the machining deviation within a few μm.

* Note: Temperature control in the machining room is required separately from our system. - Yasda’s original curvic coupling pallet chucking system sustains outstandingly high repeatability in work changes within a few μm. This is ideal for automation with PLS and FMS.

- Outstandingly long machine life with minimum deterioration of accuracy. In one example, a 22 years old Yasda Precision Center YBM60N still holds ±2μm positioning accuracy.

- Many years of our engineers’ experience in precision parts finishing, not only regarding our machines, but also tooling, jig & fixtures, cutting conditions, temperature and environment control, process through machining until measuring, etc.