Following global developments and growth of production such as high performance motors and plastic containers, etc., the accuracy of mold bases has dramatically increased.

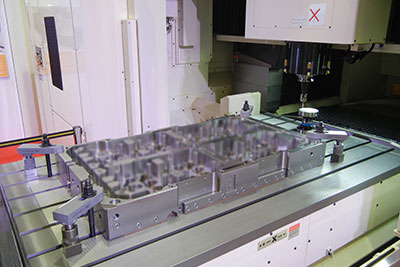

Yasda developed the YBM1218V Precision Machine Tool in 1998 to provide the highest finish accurate machining for mold bases. Our goal in developing the YBM1218V was to reduce or eliminate the processes of jig-grinding and the manual polish processes, thereby reducing the customers’ manual polish process to less than 50%. The first YBM1218V ever installed at the Yasda Japan factory is still working today without loss of machining accuracy within a few μm.

We also have excellent customer installation references for mold bases with our smaller size vertical YBM950V and YBM9150V Precision Machine Tools (previously the YBM8120V developed in 1988), and also with our Micro machining center YMC430 that specializes in mold bases for optical lenses.

Our in-depth knowledge of the technology of mold base finishing includes:

- The highest finish milling accuracy among this size machining center, second to none.

- High quality end mill contouring to finish multiple holes faster but comparable to a boring process in terms of accuracy. (This requires considering the L/D ratio of cutters.)

- Ra surface < 0.2-0.3μm, reducing a lot of the jig grinding process, even omitting it in some cases.

- Improving the milled accuracy of the mold bases helps reduce the pre-assembly process of the mold bases and their adjustment.

- Examples: Pitch accuracy of holes < ±3μm for smaller bases, < ±5μm for the size of YBM1218V. Squareness of pockets < 3μm. In the case of the YMC series, pitch accuracy of holes < ±1μm (No boring capability due to HSK-E32 taper.)

- Equally precise finishing performance is possible regardless of the hardness of the base material, no question about NAK, DAC materials, up to ca.62HRC hardened steel.

- Detailed know-how to make the best use of our machines to achieve the highest accuracy on mold bases: Temperature controls, required preparations, work piece set-up, compensations, selection of cutters, cutting conditions and programing, etc.

- Latest options to measure the angle and flatness of the work pieces more precisely (i-Gauge).

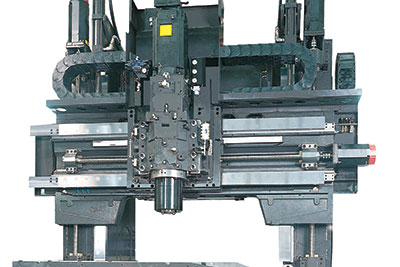

- 2 pallet changer is available for both the YBM1218V and the YBM9150V for automation.

- Key customer references for mold base manufacturing in each major country.