Following the recent growth of industries such as medical, IT, automotive, connectors, optical, plastic injection, etc., mold forms are becoming smaller and much more precise.

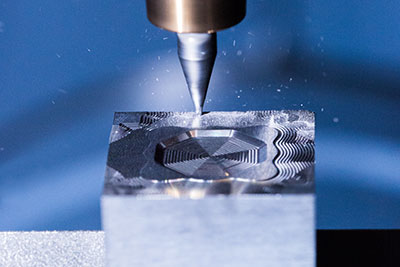

The demand for hard milling for these types of micro molds has dramatically increased. This type of mold requires a smoother surface and finer corners, more precision in each dimension, as well as faster milling time. In 2009 Yasda developed our Micro Machining Center YMC430, which abolished ball screws and has employed linear motors.

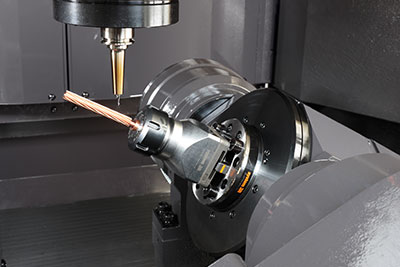

The outstanding accuracy of the YMC430 (with ten times higher positioning accuracy of our YBM V-series) achieved significant results in improving micro milling technology. The concept of the YMC430 is to achieve the highest micro milling accuracy in a temperature controlled environment of mold shops. In order to meet future demand, Yasda developed an original tilting rotary table and DD motors with no backlash, called RT10.

Today the new larger Micro Center YMC650 has been developed and introduced in the US, together with the option of our original tilting rotary table RT20.

Our in-depth knowledge of the technology of micro milling includes:

- No backlash in any linear motion or the tilting and rotary motion due to linear and DD motors. Positioning accuracy 0.1μm (JIS), < 1 arc sec. (JIS).

- Hard milling on the hardened steel 60HRC or even harder, 3 and 5-Axis. Experience with CBN end mills, diamond coated end mills, and PCD end mills.

- Finish milling on cemented carbide work pieces 3 and 5-Axis.

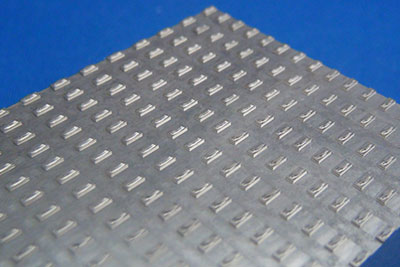

- Examples: Ra surface < 20nm, pitch accuracy < ±1μm with 3-Axis

- Versatility: Though our spindle is small 40,000 rpm HSK-E32, it can make pocket roughing on hardened steel e.g. with R8 end mills.

- Automation of hard finish milling 3 and 5-Axis, adding robot work changer or our pallet changer.

- Experience with oscillation grinding, and with wet graphite milling.

- Optional integrated air spindle 80,000 rpm is available for YMC430 specially for finishing optical molds (only available for YMC430). Ra surface 8 – 14nm.

- Advanced tool measuring systems measure tool nose with spindle rotation (DynaVision, DynaLine), Thermal distortion stabilizing system, Z-axis tool nose control system (Flat Checker), Tool posture measuring (DynaLine), Work angle measuring (i-Gauge), optional Tilted work error compensation, etc.

- Suitable work pieces: Optical molds, Lens molds, Fuel separator molds for batteries, Connector molds, Medical molds, Punch dies, Plastic or Silicon molds, Gears, Small mold base for lenses, etc.